The Versatility Of Sodium Silicate Liquid Glass: Applications And Benefits

Discover the endless possibilities of sodium silicate liquid glass in our informative article on its various applications and benefits. From industrial uses to household solutions, sodium silicate offers a wide range of advantages that can revolutionize multiple industries. Join us as we explore the versatility of this powerful substance and uncover how it can enhance your everyday life.

- Understanding Sodium Silicate Liquid Glass

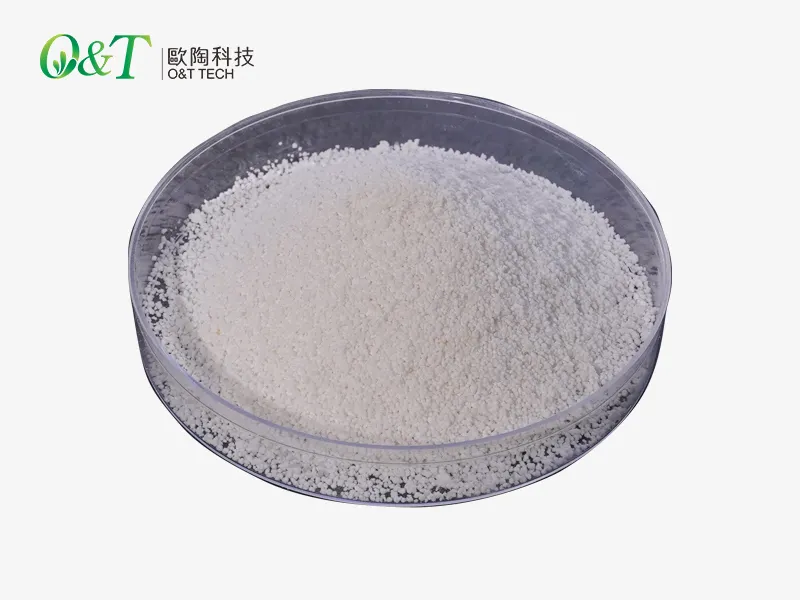

Sodium silicate liquid glass, also known as water glass, is a versatile and widely-used chemical compound with a wide range of applications and benefits. This article will delve into the various uses and advantages of sodium silicate liquid glass to provide a comprehensive understanding of its versatility.

Sodium silicate liquid glass is a compound derived from sodium oxide and silica, which are combined in a specific ratio to form a viscous liquid. It is known for its adhesive properties, which make it an ideal binding agent in various industries. One of the key applications of sodium silicate liquid glass is in paper production, where it is used as a binding agent to strengthen paper fibers and improve the overall quality of the finished product. Its ability to form strong bonds when dried makes it an essential ingredient in paper manufacturing.

Another important use of sodium silicate liquid glass is in the production of detergents and soaps. It acts as a stabilizing agent and provides alkalinity to the cleaning solutions, making them more effective at removing dirt and grime. Sodium silicate liquid glass is also used in the formulation of fire retardants, where its heat-resistant properties help to improve the safety of buildings and materials.

In the construction industry, sodium silicate liquid glass is utilized as a sealant and waterproofing agent. Its ability to form a durable and impermeable film makes it an excellent choice for protecting concrete surfaces from water damage and corrosion. Additionally, sodium silicate liquid glass is used as a binder in cement mixtures to increase their strength and durability.

In the automotive sector, sodium silicate liquid glass is employed as a coolant additive to help regulate engine temperature and prevent overheating. Its high heat tolerance and corrosion-resistant properties make it an ideal choice for this application. Furthermore, sodium silicate liquid glass is used in metal casting and welding processes to create strong and durable bonds between metal surfaces.

Aside from its industrial applications, sodium silicate liquid glass also has various benefits for the environment. It is non-toxic and biodegradable, making it an eco-friendly alternative to traditional chemical compounds. Its ability to form strong and long-lasting bonds reduces the need for frequent repairs and replacements, which helps to conserve resources and reduce waste.

In conclusion, sodium silicate liquid glass is a versatile and indispensable chemical compound with a wide range of applications and benefits. From paper production to construction, automotive, and environmental protection, its adhesive properties and heat-resistant properties make it a valuable ingredient in many industries. By understanding the versatility of sodium silicate liquid glass, we can harness its potential to improve the quality and sustainability of various products and processes.

- Various Applications of Sodium Silicate Liquid Glass

Sodium silicate liquid glass is a versatile and widely-used product that has a multitude of applications across various industries. This unique substance, also known as water glass, is a compound of sodium oxide and silica that forms a clear, viscous liquid when dissolved in water. Its versatility stems from its ability to harden into a rigid, glass-like substance when exposed to heat, making it ideal for a wide range of practical and creative uses.

One of the most common applications of sodium silicate liquid glass is as a sealant and adhesive. Its adhesive properties make it a popular choice for bonding materials such as metal, glass, and ceramics, providing a strong and durable bond that is resistant to heat and chemicals. Its sealing properties also make it an effective barrier against moisture and air, making it an ideal choice for waterproofing and weatherproofing applications.

In addition to its adhesive and sealing properties, sodium silicate liquid glass is also valued for its fire-resistant properties. When exposed to high temperatures, the liquid glass hardens into a protective layer that can withstand extreme heat, making it an ideal choice for fireproofing materials and structures. This property has made sodium silicate liquid glass a popular choice for use in fireproof coatings, insulation materials, and even as a flame retardant for textiles.

Another key application of sodium silicate liquid glass is in the field of ceramics and pottery. Its ability to harden into a rigid, glass-like substance when exposed to heat makes it an ideal binder for clay and other ceramic materials. This property allows for the creation of strong and durable ceramic objects that are impervious to water and chemicals, making them ideal for use in a wide range of applications.

Furthermore, sodium silicate liquid glass is also used in the production of detergents and soaps. Its alkaline properties make it an effective cleaning agent that can break down oils and greases, making it a popular choice for industrial and household cleaning products. Its ability to form a protective barrier on surfaces also makes it ideal for use in rust inhibitors and surface coatings.

Overall, sodium silicate liquid glass is a versatile and valuable product that has a wide range of applications across various industries. From adhesive and sealant to fireproofing and ceramics, this unique substance offers a multitude of benefits and practical uses. Its ability to harden into a glass-like substance when exposed to heat makes it an ideal choice for a wide range of applications, making it a valuable asset in any industry that requires strong, durable, and heat-resistant materials.

- Benefits of Using Sodium Silicate Liquid Glass

Sodium silicate liquid glass, also known as water glass, is a versatile and multifunctional substance that is used in a variety of industries for various applications. This powerful compound is a combination of sodium oxide and silicon dioxide, making it a versatile material with a wide range of properties.

One of the key benefits of using sodium silicate liquid glass is its adhesive properties. It is a strong adhesive that can bond a wide variety of materials together, such as glass, metal, ceramics, and even some plastics. This makes it an invaluable tool for manufacturers who need a reliable and durable adhesive for their products.

In addition to its adhesive properties, sodium silicate liquid glass is also highly resistant to heat and chemicals. This makes it an ideal material for high-temperature applications, such as in the production of glassware and ceramics. Its resistance to chemicals also makes it a popular choice for use in industrial cleaning products, as it can effectively remove grease, oil, and other tough stains.

Furthermore, sodium silicate liquid glass is a cost-effective material that is readily available and easy to use. It can be easily mixed with water to create a solution that can be applied with a brush, roller, or spray gun. Once applied, it dries quickly to form a strong and durable bond that is resistant to water, heat, and chemicals.

Another benefit of using sodium silicate liquid glass is its versatility. It can be used in a wide range of applications, from repairing cracked glass and metal surfaces to sealing porous materials and even creating decorative finishes. Its versatility makes it a valuable tool for DIY enthusiasts, as well as professionals in various industries.

Overall, sodium silicate liquid glass is a highly versatile and valuable material that offers numerous benefits for a variety of applications. Its adhesive properties, resistance to heat and chemicals, cost-effectiveness, and versatility make it a popular choice for manufacturers, cleaners, and DIY enthusiasts alike. Whether you are looking to bond materials together, seal surfaces, or create decorative finishes, sodium silicate liquid glass is a versatile and reliable solution that can meet your needs.

- Environmental Impact of Sodium Silicate Liquid Glass

Sodium silicate liquid glass, also known as water glass, is a versatile and widely used compound that has a myriad of applications across various industries. From household products to industrial processes, sodium silicate liquid glass offers a range of benefits that make it a valuable ingredient in many products and processes. However, it is essential to consider the environmental impact of sodium silicate liquid glass, as its production and use can have both positive and negative effects on the environment.

Sodium silicate liquid glass is a compound that is made from sodium oxide and silica, which are both naturally occurring minerals. The process of producing sodium silicate involves heating these minerals together to form a liquid solution that can be used in various applications. One of the key benefits of sodium silicate liquid glass is its ability to act as a binding agent, adhesive, and sealing agent. This makes it a valuable ingredient in products such as detergents, adhesives, sealants, and even some food products.

In addition to its versatile applications, sodium silicate liquid glass also offers several environmental benefits. For example, sodium silicate is non-toxic and biodegradable, which means that it does not pose a threat to human health or the environment when used in products. Additionally, sodium silicate is a renewable resource, as it is made from naturally occurring minerals that can be replenished over time. This makes sodium silicate a more sustainable alternative to synthetic chemicals that can have harmful effects on the environment.

However, it is important to consider the environmental impact of sodium silicate liquid glass production and use. While sodium silicate itself is non-toxic and biodegradable, the process of manufacturing sodium silicate can have negative effects on the environment. For example, the extraction and processing of raw materials used to make sodium silicate can contribute to air and water pollution, as well as habitat destruction. Additionally, the disposal of sodium silicate waste products can also have harmful effects on the environment if not properly managed.

To minimize the environmental impact of sodium silicate liquid glass, manufacturers and users can take steps to reduce their carbon footprint and minimize waste. For example, using recycled materials in the production of sodium silicate can help reduce the need for new raw materials, while proper waste management practices can ensure that sodium silicate waste products are disposed of in an environmentally responsible manner. Additionally, using sodium silicate in products that have a lower environmental impact, such as biodegradable detergents and sealants, can help promote sustainability and reduce overall environmental harm.

In conclusion, sodium silicate liquid glass is a versatile compound that offers a range of benefits in various applications. While sodium silicate itself is non-toxic and biodegradable, it is important to consider the environmental impact of its production and use. By taking steps to minimize the environmental impact of sodium silicate liquid glass, manufacturers and users can help promote sustainability and reduce harm to the environment.

- Future Trends in Sodium Silicate Liquid Glass Technology

Sodium silicate liquid glass, also known as water glass, is a versatile material that has found a wide range of applications in various industries. In recent years, there has been an increasing focus on the future trends in sodium silicate liquid glass technology, as researchers and manufacturers continue to explore new ways to harness its unique properties for innovative applications.

One of the key trends in sodium silicate liquid glass technology is the development of advanced formulations that offer improved performance and durability. By modifying the composition of sodium silicate, researchers are able to tailor its properties to meet specific industry requirements, such as increased heat resistance, chemical stability, and mechanical strength. This trend is particularly relevant in industries such as automotive, construction, and electronics, where there is a growing demand for high-performance materials that can withstand harsh operating conditions.

Another important trend in sodium silicate liquid glass technology is the exploration of new applications in emerging fields such as nanotechnology and biotechnology. Researchers are investigating the use of sodium silicate as a precursor for the synthesis of novel nanoparticles and nanostructured materials, which have potential applications in drug delivery, catalysis, and sensor technology. In addition, sodium silicate has been shown to have antimicrobial properties, making it a promising candidate for use in medical devices and healthcare products.

Furthermore, the environmental sustainability of sodium silicate liquid glass is driving the development of eco-friendly solutions in various industries. As a non-toxic and biodegradable material, sodium silicate is being increasingly used as an alternative to traditional fossil fuel-based chemicals in manufacturing processes. Its ability to act as a binding agent in construction materials, such as concrete and ceramics, is also contributing to the reduction of carbon emissions and environmental impact.

In conclusion, the future trends in sodium silicate liquid glass technology are driven by the desire to create advanced materials that offer improved performance, sustainability, and versatility. As researchers continue to explore the potential applications of sodium silicate in various industries, we can expect to see further innovations that will shape the future of materials science and technology. With its unique properties and wide range of applications, sodium silicate liquid glass is poised to play a significant role in the development of next-generation materials and technologies.

Conclusion

In conclusion, the versatility of sodium silicate liquid glass is truly impressive, with a wide range of applications and numerous benefits. From its use in construction and automotive industries to its role in chemistry and art, sodium silicate liquid glass has proved to be a valuable and indispensable material. Its unique properties, such as high heat resistance and adhesive strength, make it a versatile and cost-effective solution for many different projects. As technology continues to advance, the applications of sodium silicate liquid glass will likely only continue to grow, offering even more benefits and possibilities for innovation in the future. Whether you are a DIY enthusiast, a scientist, or an industrial professional, sodium silicate liquid glass is a material worth considering for your next project.

Contact person: AMY

Tel: +86-136 7405 5802

WhatsApp: +86-136 7405 5802

E-mail: amy@outao.com

Address:12th floor Ganshang Building, Zero-One industrial park, No.62 west Langbao road, Chancheng District, Foshan city, Guangdong, China (P.c.: 528051)